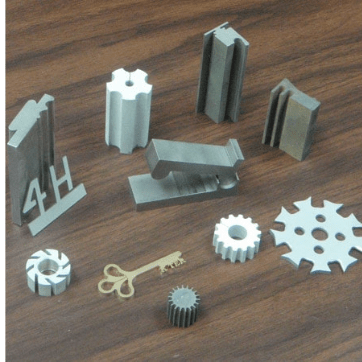

We provide Wire EDM services for the CNC machining of complex conductive metal parts used in a variety of applications, such as single station dies and progressive dies. Parts with complex geometries can be produced from a wide range of materials, including stainless steel and aluminum, with our EDM services.

Parts of up to 19.7″ by 13.8″ by 11.8″ in size and weights up to 1764 lbs can be manufactured in our 4-axis Wire EDM machines. In addition, our Mitsubishi Model FX20 wire EDM machine, outfitted with an automatic wire threader, can cut with a maximum taper angle of +/-15° in metals with 3.94″ thickness. Quick turnarounds are easily facilitated on all Wire EDM jobs.

WIRE EDM CAPABILITIES

- Maximum Part Size

19.2 x 13.8 x 11.8 inches

- Applications

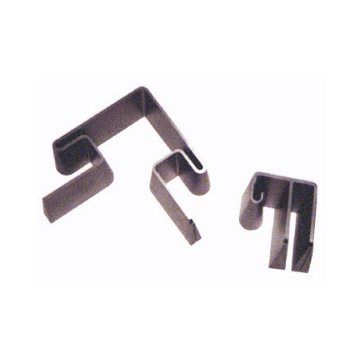

Metal Stamping Dies: Pierce, Form & Cut Off Dies

Production & Automation Equipment

Prototypes

- Industries Served

Manufacturing

Packaging

Gas Meter

1st Tier Automotive

- Standards

OSHA

- Design and Engineering Capabilities

2 Seat CAM

5 Seat CAD

CadKey

Solidworks 2012

MasterCam 16

Equipment Specifications

- Mitsubishi Model FX20 - Wire EDM

Auto Wire Feed

Axes: 4

Maximum Weight: 1764 lbs

Work Envelope: X-Axis 19.2, Y-Axis 13.8, Z-Axis 11.8

- Mitsubishi Model DWC110 C2 - Wire EDM

Axes: 4

Maximum Weight: 1100 lbs

Work Envelope: X-Axis 11.8, Y-Axis 17.7, Z-Axis 10.0