K-Ter Imagineering Inc. was established in 1981 with the primary goal of supplying vinyl siding manufacturers with a turnkey line of machines and tooling for their production. We started with the basic machines, the Embosser, Cooling Rolls, Cooling Tank, Puller, Nail Hole and Weep Hole Punches, and Cut Off Machine along with the Sizers or Forming Calibrators and Shear or Crop Dies. We quickly added a variety of other accessory equipment and went on to develop the most successful semi-automated and the only fully-automatic packaging systems on the market.

Our founder, Bob Szabo, developed the Post-Form method of manufacturing vinyl siding. Early on, we pioneered the use of large water cooled cooling rolls and later developed the patented Water Dip System. We developed the one piece Nail Hole Punch disk that is almost universal today. We also hold a patent for our packaging system.

We are still the only vinyl siding equipment manufacturer able to offer a complete downstream system, built in house so we can insure the quality and be your one stop source.

VINYL EXTRUSION EQUIPMENT CAPABILITIES

- Vinyl Extrusion Equipment

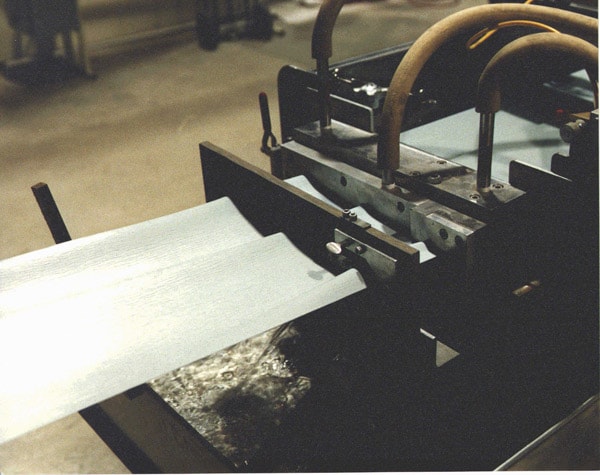

Embossing-Machines (PDF – 146KB)

Embossing-Machines (PDF – 146KB) Water-Dip-Cooling-Systems (PDF – 149KB)

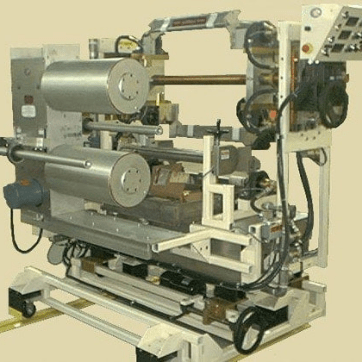

Water-Dip-Cooling-Systems (PDF – 149KB) Cooling-Rolls (PDF – 127KB)

Cooling-Rolls (PDF – 127KB) Calibrators-or-Sizers (PDF – 109KB)

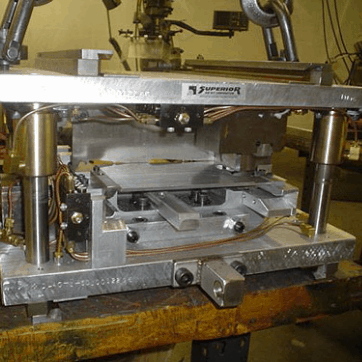

Calibrators-or-Sizers (PDF – 109KB) Water-Tank (PDF – 154KB)

Water-Tank (PDF – 154KB) Air-Knife-System (PDF – 158KB)

Air-Knife-System (PDF – 158KB) Nail-Hole-Punch (PDF – 137KB)

Nail-Hole-Punch (PDF – 137KB) Weep-Hole-Punch (PDF – 149KB)

Weep-Hole-Punch (PDF – 149KB) Puller (PDF – 155KB)

Puller (PDF – 155KB) Cut-Off-Press (PDF – 136KB)

Cut-Off-Press (PDF – 136KB) Cut-Off-Dies (PDF – 130KB)

Cut-Off-Dies (PDF – 130KB) Rotary-Scrap-Cutter (PDF – 114KB)

Rotary-Scrap-Cutter (PDF – 114KB) Soffit-Venting-Machines (PDF – 271KB)

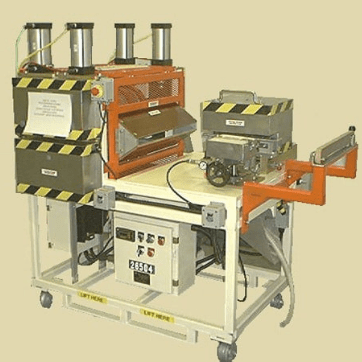

Soffit-Venting-Machines (PDF – 271KB) Semi-Automatic—Totally-Automatic-Packaging (PDF – 720KB)

Semi-Automatic—Totally-Automatic-Packaging (PDF – 720KB)

- Automation

Electrical

Mechanical

PLC programming

Pneumatic and Hydraulic Control Systems Engineered and Built

- Safety Guarding Options

Labels that warn of missing guards

OSHA standards

Proper fusing and grounding

Safety color coded parts

Safety disconnects for all sources of power

Safety interlocks on critical guards

- Other Features

All stainless steel water plumbing

Forklift straps on the frames

Powder coating

Rail mounted machinery

Stainless steel guards

- Standards

OSHA

- Industries Served

Vinyl Siding

Manufacturing

Packaging

Food

Gas Meter

1st Tier Automotive

Equipment Specifications

- Hurco VM-30 Vertical CNC Milling Center

20 Station Tool Magazine

10,000 RPM Spindle

Travel of X-Axis 50″

Y-Axis 20″

Z-Axis 20″

- Mori Seiki MV-45 Vertical CNC Milling Center

24 Station Tool Magazine

Travel: X-Axis 30″, Y-Axis 17.7″, Z-Axis 19.7″

- Mori Seiki MV-55 Vertical Milling Center

24 Station Tool Magazine

Travel: X-Axis 40″, Y-Axis 21.7″, Z-Axis 21.7″

- Mitsubishi Model FX20 - Wire EDM

Auto Wire Feed

Axes: 4

Maximum Weight: 1764 lbs

Work Envelope: X-Axis 19.2, Y-Axis 13.8, Z-Axis 11.8

- Mitsubishi Model DWC110 C2 - Wire EDM

Axes: 4

Maximum Weight: 1100 lbs

Work Envelope: X-Axis 11.8, Y-Axis 17.7, Z-Axis 10.0

- Elox Model Q - Wire EDM

Axes: 4

Maximum Weight: 660 lbs

Work Envelope: X-Axis 13.8, Y-Axis 19.5, Z-Axis 7.0

- Elox Model L - Wire EDM

Axes: 4

Maximum Weight: 352 lbs

Work Envelope: X-Axis 9.8, Y-Axis 13.7, Z-Axis 7.0